-

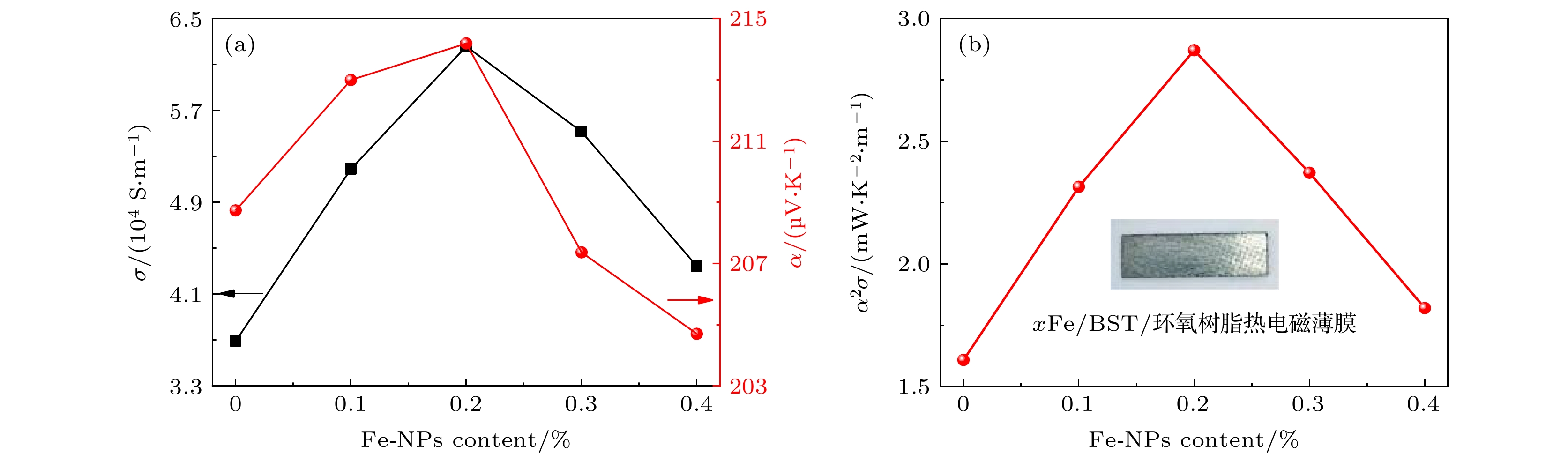

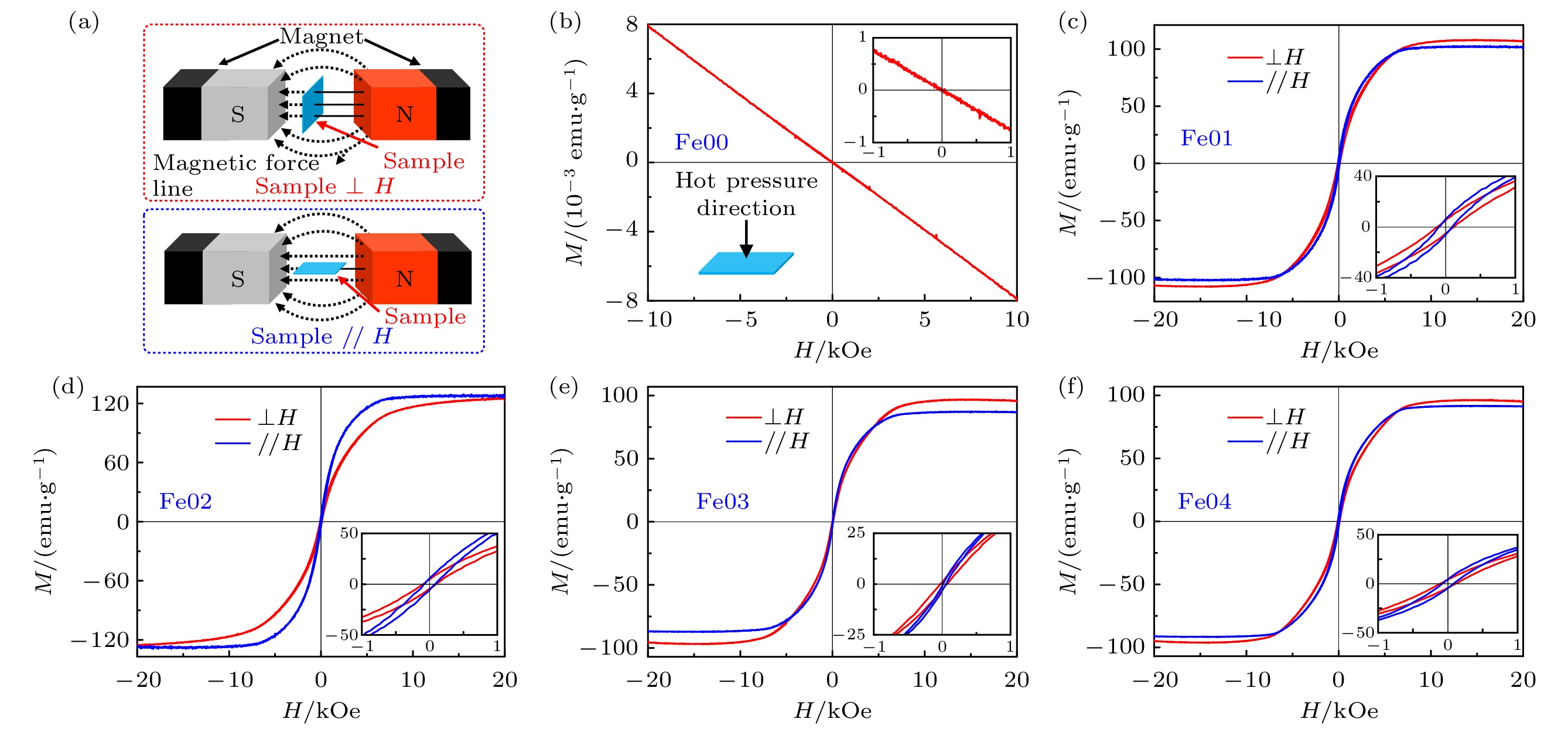

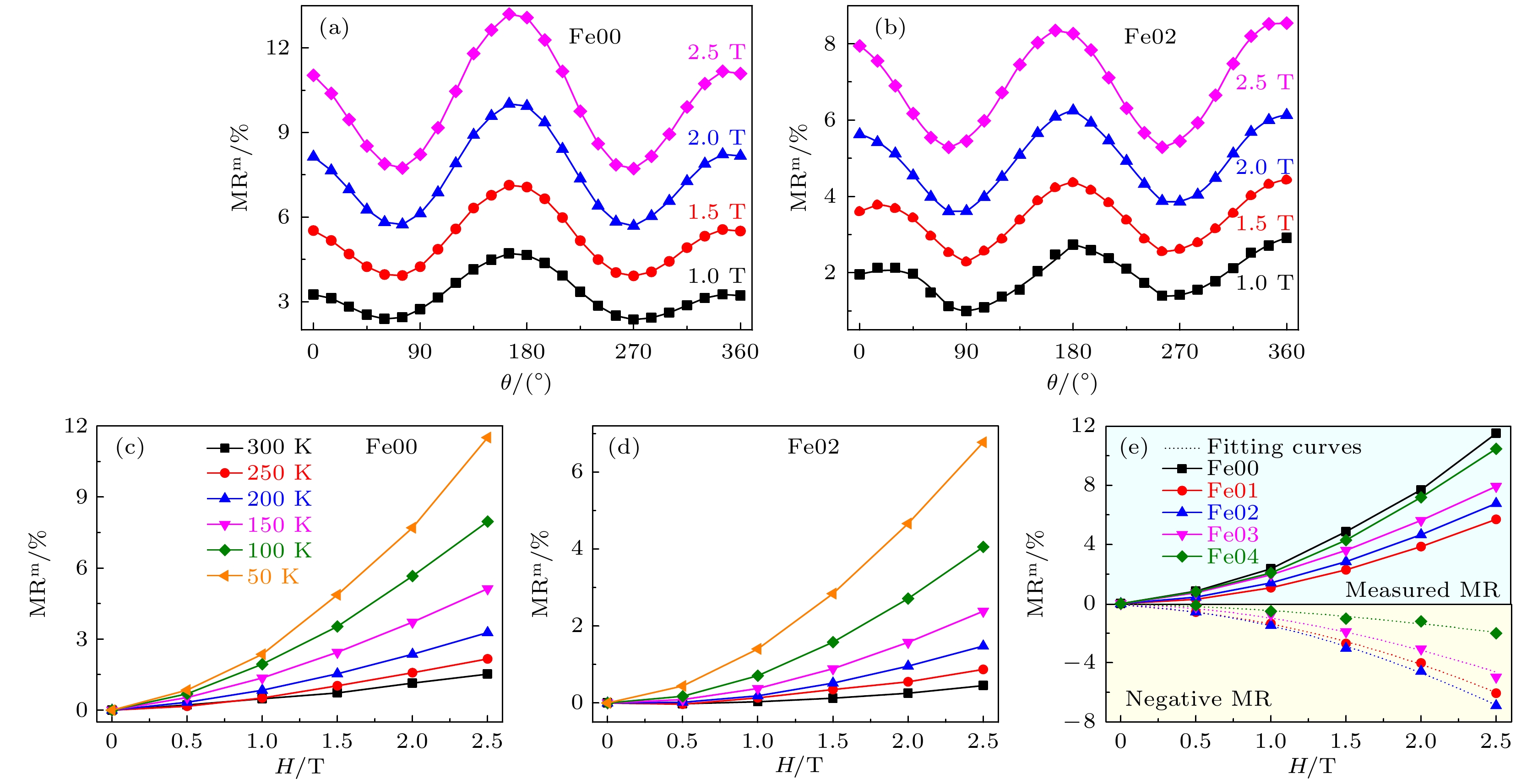

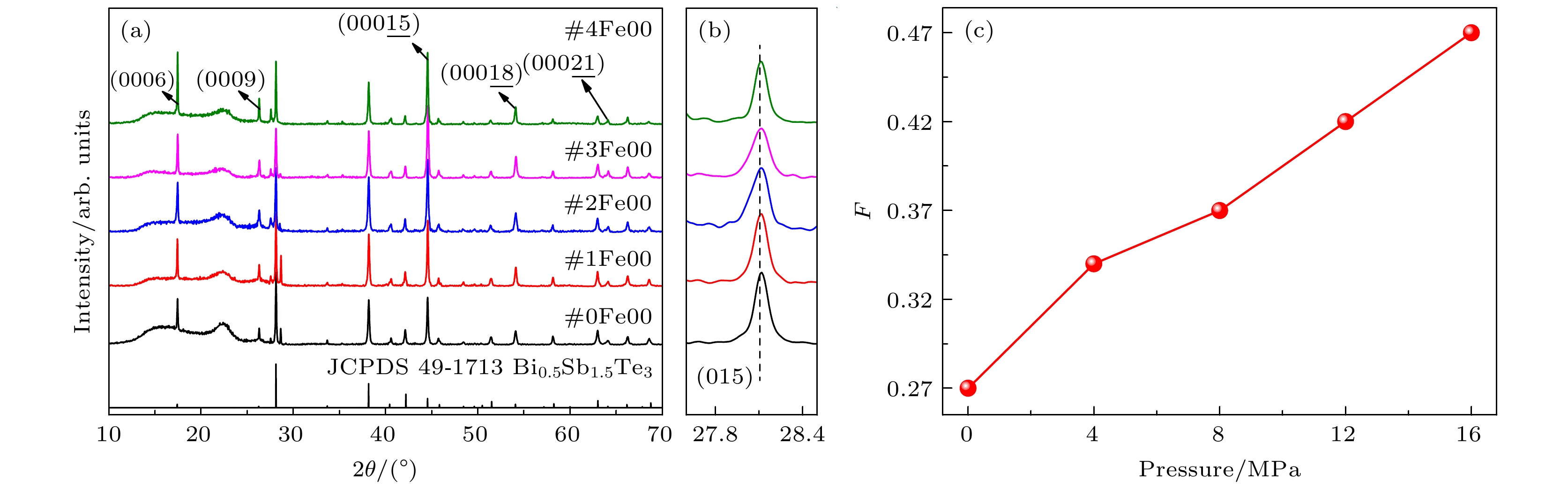

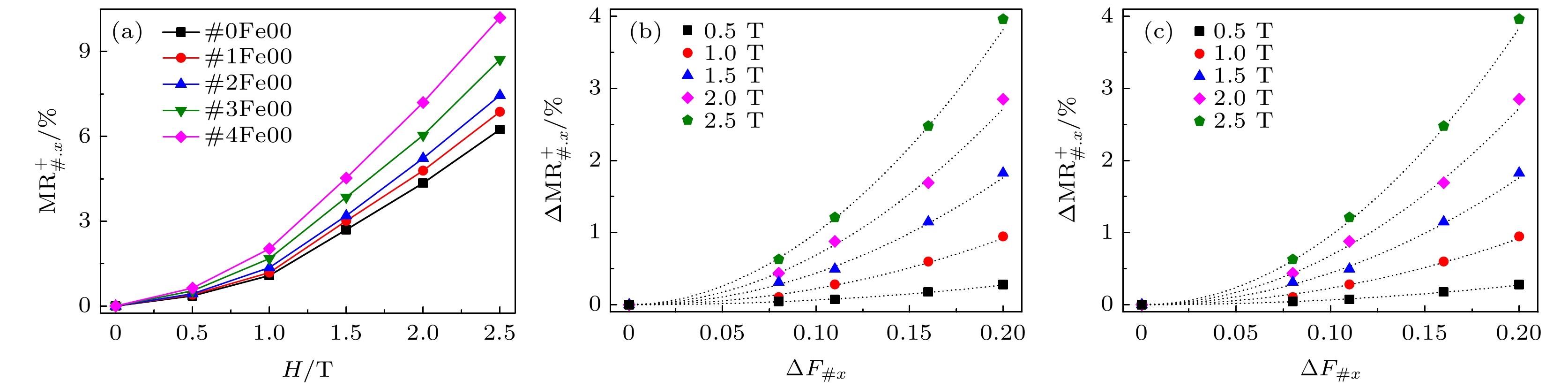

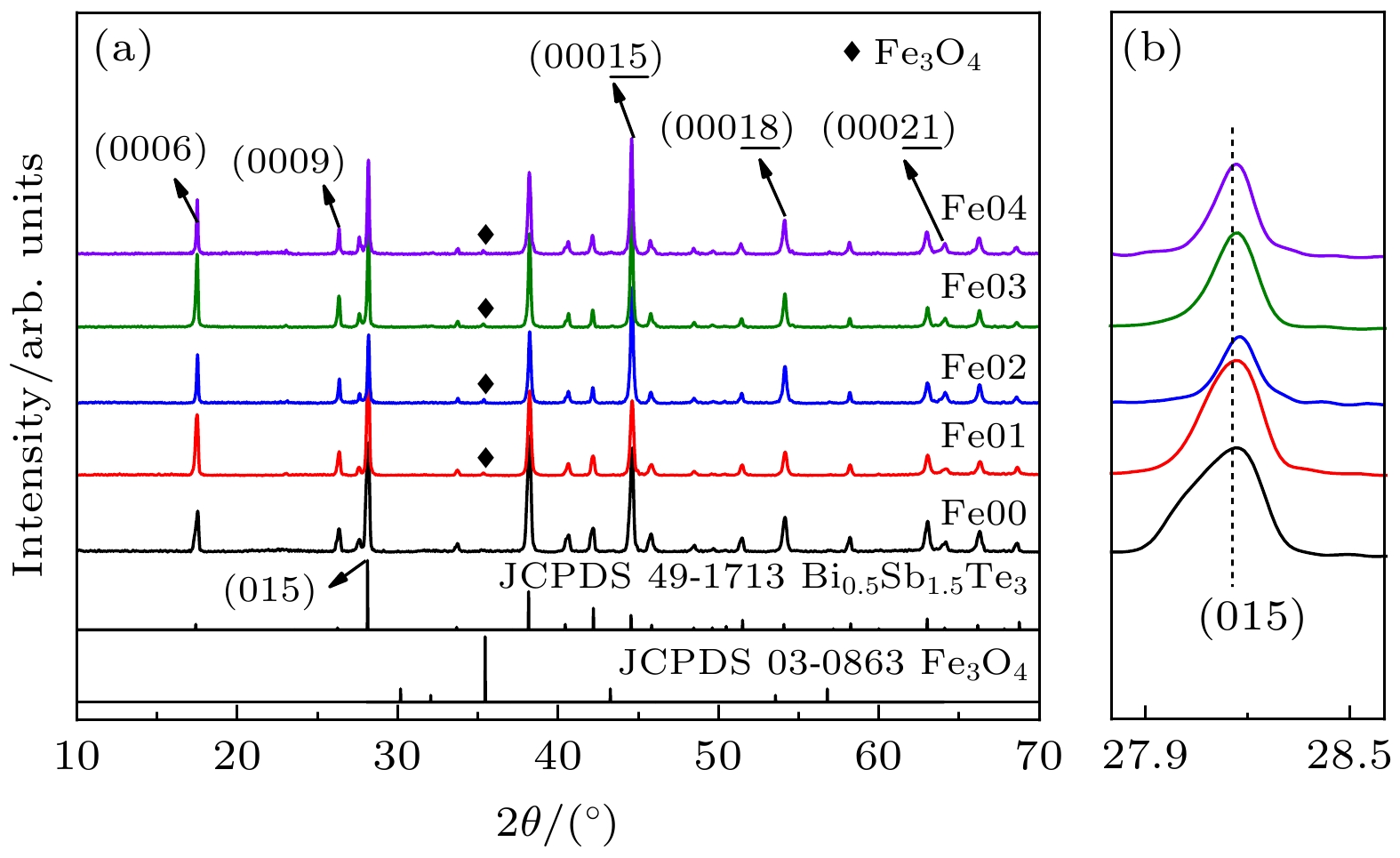

具有优异电输运性能的热电薄膜是发展高效面内散热技术的关键材料, 但是过低的电输运性能是制约其应用的重要难题. 热电磁耦合新效应是近年来发展的一种优化综合热电性能的新方法. 为了探索热电磁耦合新效应对热电薄膜电输运性能的影响机制, 本研究发展了一种球磨分散-丝网印刷-热压固化一体化成型的方法, 成功制备了一系列Fe纳米粒子作为第二相的 xFe/BST/环氧树脂热电磁薄膜, 并重点研究了其热电磁耦合作用及其对电热输运性能的影响规律. 研究发现, xFe/Bi 0.5Sb 1.5Te 3(BST)/环氧树脂热电磁薄膜中存在正、负磁阻共存的现象; BST(000 l)择优取向因子与正磁阻(MR +)之间呈正比例关系并增加热电磁薄膜的电导率; 源于强铁磁性Fe纳米粒子局部磁矩的自旋相关散射的负磁阻(MR –)会增加Seebeck系数. 因此, 室温附近Fe/BST/环氧树脂热电磁薄膜的功率因子高达2.87 mW/(K 2·m), 与BST/环氧树脂热电薄膜相比, 提高了78%. 这些结果表明, 热电磁薄膜中正、负磁阻的共存不仅可解耦热电材料中电导率与Seebeck系数之间的耦合关系, 还可以为磁纳米粒子诱导优异热电转换性能提供新的物理机制.

-

关键词:

- p型Bi2Te3基热电磁薄膜/

- 磁各向异性/

- 磁阻/

- 自旋相关散射

Thermoelectric (TE) films with excellent electrical transport property are key materials for developing efficient in-plane heat dissipation technology, but their low electrical transport property is a challenge that restricts their application. Recently, a new thermo-electro-magnetic coupling effect has been proposed to significantly improve the comprehensive TE performance. In order to explore the influence of the above effects on the electric transport property of TE films, we develop an integrated preparation method through ball milling dispersion, screen-printing and hot-pressing curing, obtaining a series of xFe/Bi 0.5Sb 1.5Te 3(BST)/epoxy TE films in which Fe nanoparticles serve as the second phase, resulting in the thermo-electro-magnetic coupling effect , and also we study their influence on the electrothermal transport performance. The results are shown below. The positive and negative magnetoresistance are co-existent in xFe/BST/epoxy thermoelectromagnetic films; the preferred orientation factor of BST (000 l) is positively proportional to the positive magnetoresistance (MR +), resulting in an increase of the conductivity; the spin-dependent scattering of negative magnetoresistance (MR –) derived from the local magnetic moment of strong ferromagnetic Fe nanoparticles increases the Seebeck coefficient. Hence, the power factor of Fe/BST/epoxy thermoelectromagnetic film near room temperature reaches 2.87 mW⋅K –2⋅m –1, which is 78% higher than that of BST/epoxy thermoelectric film. These results indicate that the coexistence of positive and negative magnetoresistance in thermoelectromagnetic films can not only relieve the coupling relationship between conductivity and Seebeck coefficient in TE materials, but also provide a new physical mechanism for the excellent TE conversion performance induced by magnetic nanoparticles.-

Keywords:

- p-type Bi2Te3based thermoelectromagnetic films/

- magnetic anisotropy/

- magnetoresistance/

- spin dependent scattering

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] -

No. F ΔF 0.5 T 1.0 T 1.5 T 2.0 T 2.5 T MRm MR+ MR– MRm MR+ MR– MRm MR+ MR– MRm MR+ MR– MRm MR+ MR– Fe00 0.26 0.00 0.85 0.85 0.00 2.36 2.36 0.00 4.87 4.87 0.00 7.70 7.70 0.00 11.51 11.51 0.00 Fe01 0.31 0.05 0.30 0.86 –0.57 1.07 2.42 –1.34 2.29 4.98 –2.69 3.86 7.87 –4.01 5.70 11.75 –6.05 Fe02 0.41 0.15 0.44 1.00 –0.56 1.41 2.87 –1.50 2.84 5.86 –3.02 4.66 9.24 –4.57 6.78 13.67 –6.90 Fe03 0.38 0.12 0.73 0.94 –0.21 1.96 2.69 –0.73 3.61 5.50 –1.90 5.63 8.68 –3.06 7.93 12.89 –4.96 Fe04 0.36 0.10 0.80 0.92 –0.11 2.08 2.59 –0.51 4.30 5.31 –1.01 7.19 8.38 –1.19 10.47 12.47 –2.00 Samples x Ms/(emu·g–1) Hk/Oe Keff/(105erg·g–1) ΔE/(104erg·g–1) Hc/Oe Mr/(emu·g–1) Fe01 0.1% 107.76 9703.48 5.23 5.94 123.65 5.42 Fe02 0.2% 122.17 14456.38 8.83 8.98 93.37 4.84 Fe03 0.3% 95.80 10700.42 5.13 7.31 78.80 1.09 Fe04 0.4% 95.12 10144.43 4.82 6.23 117.48 4.14 Sample F# ΔF# 0.5 T 1.0 T 1.5 T 2.0 T 2.5 T $ {{\Delta {\mathrm{MR}}}}_{\text{\# }}^{+} $ K0 $ {{\Delta {\mathrm{MR}}}}_{\text{\# }}^{+} $ K0 $ {{\Delta {\mathrm{MR}}}}_{\text{\# }}^{+} $ K0 $ {{\Delta {\mathrm{MR}}}}_{\text{\# }}^{+} $ K0 $ {{\Delta {\mathrm{MR}}}}_{\text{\# }}^{+} $ K0 #0Fe00 0.26 0.00 0.00 26.99 0.00 22.91 0.00 19.59 0.00 17.04 0.00 15.35 #1Fe00 0.34 0.08 0.04 26.99 0.11 22.91 0.31 19.59 0.44 17.04 0.63 15.35 #2Fe00 0.37 0.11 0.07 26.99 0.28 22.91 0.49 19.59 0.88 17.04 1.21 15.35 #3Fe00 0.42 0.16 0.18 26.99 0.60 22.91 1.15 19.59 1.69 17.04 2.48 15.35 #4Fe00 0.46 0.20 0.28 26.99 0.95 22.91 1.83 19.59 2.85 17.04 3.96 15.35 No. K1 K2 K3 0.5 T 1.0 T 1.5 T 2.0 T 2.5 T $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{S}}{\mathrm{D}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{W}}{\mathrm{L}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{S}}{\mathrm{D}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{W}}{\mathrm{L}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{S}}{\mathrm{D}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{W}}{\mathrm{L}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{S}}{\mathrm{D}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{W}}{\mathrm{L}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{S}}{\mathrm{D}}}^{-} $ $ {{\mathrm{M}}{\mathrm{R}}}_{{\mathrm{W}}{\mathrm{L}}}^{-} $ Fe00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Fe01 56.30 0.12 0.52 –0.20 –0.37 –0.82 –0.52 –2.06 –0.64 –3.27 –0.74 –5.23 –0.82 Fe02 36.77 0.17 0.45 –0.24 –0.32 –1.02 –0.47 –2.47 –0.55 –3.94 –0.64 –6.18 –0.71 Fe03 19.10 0.20 0.23 –0.05 –0.16 –0.50 –0.23 –1.61 –0.28 –2.73 –0.33 –4.60 –0.36 Fe04 6.38 0.22 0.17 –0.00 –0.12 –0.34 –0.17 –0.81 –0.21 –0.95 –0.24 –1.73 –0.27 -

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28]

计量

- 文章访问数:436

- PDF下载量:6

- 被引次数:0

下载:

下载: